Have you ever wondered how automotive paint achieves that high - gloss finish?

Essential Surface Preparation for High-Gloss Automotive Paint

Thorough Cleaning and Degreasing Techniques

Achieving a flawless automotive paint job begins with thorough cleaning and degreasing of the vehicle's surface. A pH-balanced cleaner is essential as it effectively removes wax, grease, and dirt without damaging the paint. Start by washing the car with suitable tools, such as microfiber towels, to prevent scratches during the cleaning process. Ensure that all areas, including hard-to-reach spots, are meticulously cleaned. After washing, use a specialized degreaser to remove any remaining contaminants. Studies have shown that cleaner surfaces significantly enhance the adhesion of automotive paint, establishing a lasting and brilliant finish. This approach not only prepares the car for the next steps but also sets a solid foundation for high-gloss results.

Using Detailing Clay for Contaminant Removal

Detailing clay plays a crucial role in removing stubborn, bonded contaminants like tar and industrial fallout from the vehicle's surface. It is highly effective, as it can extract particles embedded in the paint, which regular washing cannot eliminate. To use detailing clay properly, apply lubrication generously to avoid marring the surface while gliding the clay over the bodywork. Experts recommend using the clay treatment at least every six months to maintain the paint's integrity and gloss, ensuring the surface remains smooth and ready for subsequent painting stages. By regularly incorporating detailing clay into your routine, you preserve the pristine condition of the automotive finish.

Sanding Imperfections for Smooth Substrates

Sanding is an indispensable part of surface preparation, ensuring a smooth substrate for high-quality paint application. Different sandpaper grits cater to various preparation stages, ultimately affecting the success of the paint job. Begin with coarser grits for major imperfections and progress to finer grits for precision work. Wet sanding techniques are often employed to minimize dust and reduce the risk of scratches, which improves paint adhesion. Moreover, block sanding is recommended for achieving flatter surfaces, essential for a mirror-like finish. By following a structured sanding approach, you facilitate a more professional and long-lasting automotive paint finish.

Polishing Techniques to Enhance Automotive Paint Gloss

Choosing the Right Polishing Compound

Selecting the appropriate polishing compound is crucial in achieving the desired gloss on automotive paint. Different compounds cater to specific needs; for instance, some are designed to remove minor scratches, while others enhance overall shine. The choice of compound must consider the type of paint—be it acrylic or polyurethane—and the desired gloss level. An understanding of these differences enables better product selection. For instance, professional detailers report a significant gloss enhancement when using specialized polishing compounds tailored to specific paint types, with some results showing up to a 30% increase in optical clarity.

Machine Buffing vs. Hand Polishing Methods

When it comes to polishing methods, both machine buffing and hand polishing have their merits. Machine buffing is more efficient and often delivers a uniform finish, making it ideal for larger surfaces or cars in need of intensive work. However, it demands caution; choosing the right pad and maintaining control is crucial to avoid damaging the paint. On the other hand, hand polishing allows for finer control and is safer for delicate areas. Many experts recommend machine buffing for significant paint correction and hand polishing for touch-ups or to achieve the final glossy finish on vehicles in pristine condition.

Achieving Uniform Reflectivity Through Layering

Layering polish can significantly impact the reflectivity of automotive paint, creating a deep, mirror-like finish. The technique involves multiple applications of polish, with proper drying time between layers to ensure each coat cures adequately. Environmental factors like temperature and humidity play a critical role in this process, as high humidity can extend curing times. According to material science studies, optimal layering leads to consistently high-gloss results. By carefully controlling these factors and employing best practices, one achieves a uniform glossy surface without swirls, thus enhancing the overall appearance of the vehicle.

Clear Coat Application for Lasting High-Gloss Protection

Spray Techniques for Flawless Clear Coat Coverage

Mastering the art of spray painting is crucial for achieving flawless clear coat coverage. It's essential to understand spray gun settings, such as pressure and nozzle size, which significantly influence the atomization of the paint and, consequently, the finish quality. Maintaining a consistent spray pattern by employing even horizontal or vertical strokes at an appropriate distance from the surface is vital. This technique minimizes the risk of developing the "orange peel" effect, where the surface resembles the skin of an orange. According to industry standards, the thickness of the clear coat plays a pivotal role in ensuring both durability and protective capability. Ensuring the clear coat is applied evenly helps in creating a high-gloss, durable finish that can withstand environmental factors.

Curing Conditions and Humidity Control

Environmental conditions play a significant role in the curing of automotive paints, impacting both the process and the final outcome. Controlled temperature and humidity are paramount to avoid issues like lifting and fisheyes. An optimal curing environment, typically around 70°F with low humidity, can prevent paint defects and ensure proper adhesion. Experts recommend adhering to prescribed curing times to allow the paint layers to set and bond effectively. High humidity can lead to uneven curing and adversely affect the paint's longevity and appearance. Therefore, maintaining the right balance of temperature and humidity is foundational to achieving a seamless paint finish.

Wet Sanding Between Coats for Optimal Smoothness

Wet sanding between clear coat layers is an effective method to attain a glass-like, smooth finish in automotive paint applications. This process involves using fine-grit sandpaper and water to carefully sand the clear coat, removing any imperfections and enhancing surface smoothness. Following a step-by-step approach is crucial: cleaning the surface thoroughly, applying even pressure during sanding, and regularly checking progress to avoid cutting through the clear coat. Expert detailers frequently cite improved gloss and longevity as significant benefits of incorporating wet sanding into the paint application process. By enhancing surface evenness, wet sanding optimizes the reflective qualities of the clear coat, contributing to a professional, high-gloss appearance.

Recommended High-Performance Automotive Paint Products

Boxcar Paint: Water-Based High-Gloss Coating System

Boxcar Paint stands out due to its eco-friendliness and exceptional high-gloss capabilities. Crafted from water-based special functional resins and anti-rust pigments, this paint not only protects against corrosion but also enhances the aesthetic appeal of vehicles with its vibrant, glossy finish. Users frequently commend its durability and longevity, praising its ability to withstand harsh environmental conditions without fading or peeling. When applying Boxcar Paint, it's crucial to maintain a clean and dry surface and follow the recommended process for optimal results, ensuring a smooth, uniform finish. For further details, you can explore Boxcar Paint.

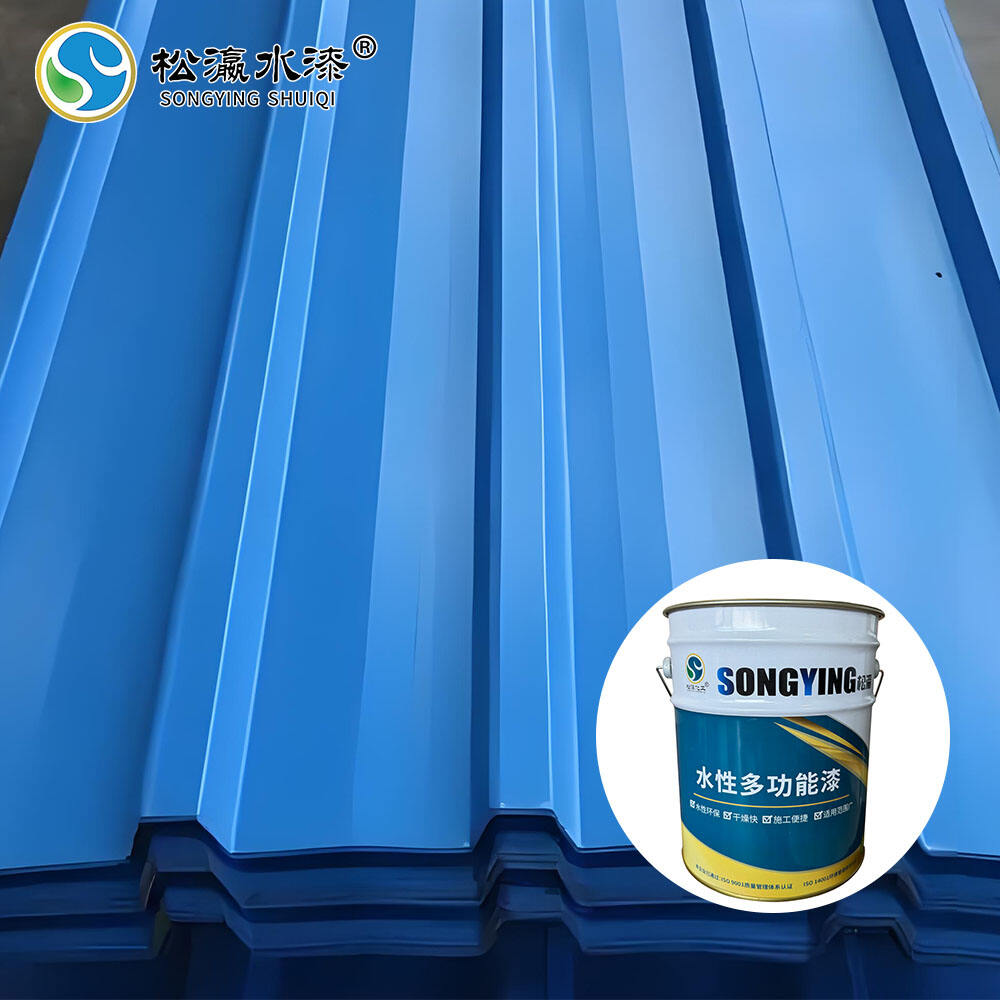

Multi-Functional Paint: Dual-Action Anti-Corrosion Formula

The Multi-Functional Paint offers a remarkable dual-action formula, delivering both a high-gloss finish and robust corrosion resistance. Prepared with water-based acrylic anti-rust resin, this innovative solution is free from organic solvents, aligning with environmental protection standards. Real-world case studies highlight its effectiveness across various challenging environments, including industrial applications. Compatibility with diverse substrates is assured when implementing the advised preparation techniques, guaranteeing a seamless application process. Whether employed on steel structures or oil pipelines, this paint excels in extending service life by over five years. Learn more about the Multi-Functional Paint.

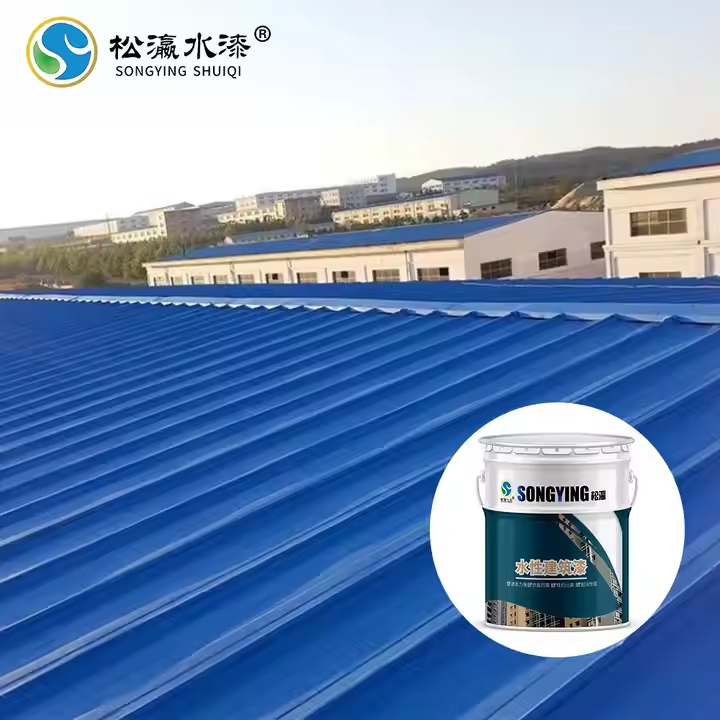

Songying Polyurethane Renovation Paint for Metal Surfaces

Songying Water-Based Polyurethane Renovation Paint is an exemplary choice for refurbishing metal surfaces, particularly roofing. Renowned for its superior high-gloss finish and scratch resistance, this paint offers both aesthetic and protective qualities, ensuring metal roofs maintain their appearance and integrity. Application guides recommend optimal environmental conditions for achieving the best results, emphasizing ease of use and rapid drying times. Compared to other products in its category, market reviews consistently highlight Songying's outstanding durability and reliability. For those seeking a dependable solution for their metal surfaces, Songying is the top choice. Discover more about Songying Polyurethane Renovation Paint.

Maintaining Your Automotive Paint's Mirror Finish

Proper Washing Methods to Prevent Micro-Scratching

Proper washing techniques are vital to maintain your automotive paint's pristine appearance and prevent micro-scratches. It's essential to use gentle, automotive-specific soaps combined with soft microfiber mitts to avoid abrasion. Research indicates these materials significantly reduce the chance of scratching compared to harsher alternatives. Moreover, adopting these best practices not only extends the paint's lifespan but also preserves its gloss, keeping your car looking fresh for longer.

Ceramic Coating Application for Extended Protection

Applying a ceramic coating offers superior protection for automotive paint, safeguarding it from harmful UV rays and chemical exposure. The process involves meticulous surface preparation and precise curing times to ensure maximum effectiveness. Experts recommend rigorous adherence to application guidelines, which includes thoroughly cleaning and drying the surface before coating. Users have found that ceramic coatings considerably enhance paint longevity, with minimal maintenance required for sustained effectiveness.

Seasonal Maintenance for UV and Weather Resistance

Seasonal maintenance is crucial in safeguarding your vehicle's paint from environmental factors such as harsh UV rays and variable weather conditions. Regular checks and maintenance routines, such as applying weather-appropriate wax, ensure the paint's resilience throughout the year. Statistics show that vehicles receiving seasonal maintenance exhibit longer-lasting paint durability. By using suitable products and techniques, you can ensure your vehicle’s surface remains robust in various climates, maintaining that mirror-like finish.

EN

EN