Jika anda berada dalam bidang penghantaran, cat kelautan adalah kawan terbaik anda. Inilah sebabnya!

Kelebihan Utama Cat Kelautan untuk Perlindungan Kapal

Keupayaan Menahan Korosi dalam Lingkungan Lautan Yang Sukan

Cat air adalah perkara penting untuk mencipta pelindung terhadap elemen-elemen yang memudarat seperti air laut dan kelembapan. Alam sekitar ini sangat keras dan boleh menyebabkan penurunan ketahanan kapal jika tidak ditangani dengan betul. Dengan menggunakan cat air, pemilik kapal dapat memanjangkan umur badan kapal mereka, mengurangkan keperluan untuk perbaikan kerap. Pengurangan dalam kos penyelenggaraan adalah faedah langsung daripada tahan karat yang berkesan yang disediakan oleh cat tersebut. Perlu diingat bahawa jenis-jenis kapal air yang berbeza, seperti bot memancing, kapal kargo, atau kapal rekreasi, mungkin memerlukan formula cat air tertentu untuk memastikan mereka mendapat perlindungan tersuai terhadap karat.

Sifat Anti-Fouling untuk Peningkatan Prestasi

Pertumbuhan organisme laut seperti kerang dan alga boleh mengorbankan prestasi sebuah kapal dengan meningkatkan rintangan. Cat anti-kotoran laut direka untuk mencegah pertumbuhan yang tidak diingini ini, memastikan kelajuan dan kecekapan bahan api yang optimum. Cat ini menggunakan biocid yang menghalang haiwan laut dari menempel pada badan kapal. Pemohonan secara berkala adalah penting untuk mengekalkan perlindungan ini, terutamanya apabila kajian dalam industri menunjukkan bahawa penapisan anti-kotoran yang dirawat baik boleh mengurangkan kos bahan api sehingga 15%. Kecekapan kos ini adalah kritikal bagi kapal perniagaan dan rekreasi yang bergantung kepada prestasi yang konsisten.

Pelindungan UV Melawan Kesan Cuaca

Cat air laut sering kali mengandungi penahan UV untuk melindungi terhadap kerosakan sinar matahari, yang boleh menyebabkan pudarnya warna dan merosakkan integriti struktur kapal. Paparan kepada matahari adalah ancaman yang berterusan dalam persekitaran maritim, yang boleh menyebabkan kos pembaikan yang tinggi jika tidak dirawat. Dengan menyertakan perlindungan UV dalam formula cat air laut, kesan ini boleh dikurangkan secara signifikan. Faedah jangka panjang dengan melaburkan perlindungan UV adalah jelas, kerana ia membantu mengekalkan daya tarik estetik dan integriti struktur kapal, sambil mengelakkan kos baikan besar yang berkaitan dengan kerosakan sinar matahari.

Memilih Cat Air Laut yang Tepat untuk Kebutuhan Anda

Membandingkan Formula Berasaskan Epoksi dengan Silicone

Apabila memilih cat kelautan untuk kapal anda, memahami perbezaan di antara formula berbasa epoksi dan silikon adalah perkara yang penting. Cat kelautan berbasa epoksi dikenali dengan kekerasannya dan ketahanan kuat terhadap geseran, menjadikannya sesuai untuk kapal-kapal yang mengalami keausan kerap, seperti kapal kargo dan bot memancing. Sebaliknya, formula silikon menawarkan fleksibiliti yang lebih besar dan tahan terhadap perubahan suhu, menjadikannya sesuai untuk kapal yang beroperasi dalam keadaan cuaca ekstrem. Ia amat penting untuk mempertimbangkan keperluan aplikasi spesifik anda kerana setiap formula mempunyai ciri-ciri prestasi yang berbeza yang sesuai untuk persekitaran laut dan senario penggunaan yang berbeza.

Kebutuhan Aplikasi untuk Jenis Kapal Berbeza

Mengecat sebuah kapal melibatkan pertimbangan berbagai faktor untuk memastikan keawetan dan keberkesanan pelapisan maritim. Jenis kapal yang berbeza, sama ada untuk rekreasi atau komersial, mempunyai teknik aplikasi unik berdasarkan bahan, berat, dan tujuan penggunaan. Sebagai contoh, persiapan permukaan adalah perkara penting; hull logam mungkin memerlukan proses priming yang berbeza berbanding kapal fiberglass, yang secara langsung mempengaruhi keselesaan pengecatan dan ketahanan keseluruhan. Selain itu, memahami masa kering dan keadaan adalah sangat penting. Sebagai contoh, pelapis lantai epoksi mungkin memerlukan teknik aplikasi yang lebih tepat dalam persekitaran lembap untuk mengelakkan pembentukan gelembung dan memastikan kelulusan yang licin. Dengan mempertimbangkan faktor-faktor ini dengan teliti, anda boleh meningkatkan ciri-ciri perlindungan dan jangka hayat cat laut yang dipilih.

SongYing Penyelesaian Pelapisan Maritim Kimia

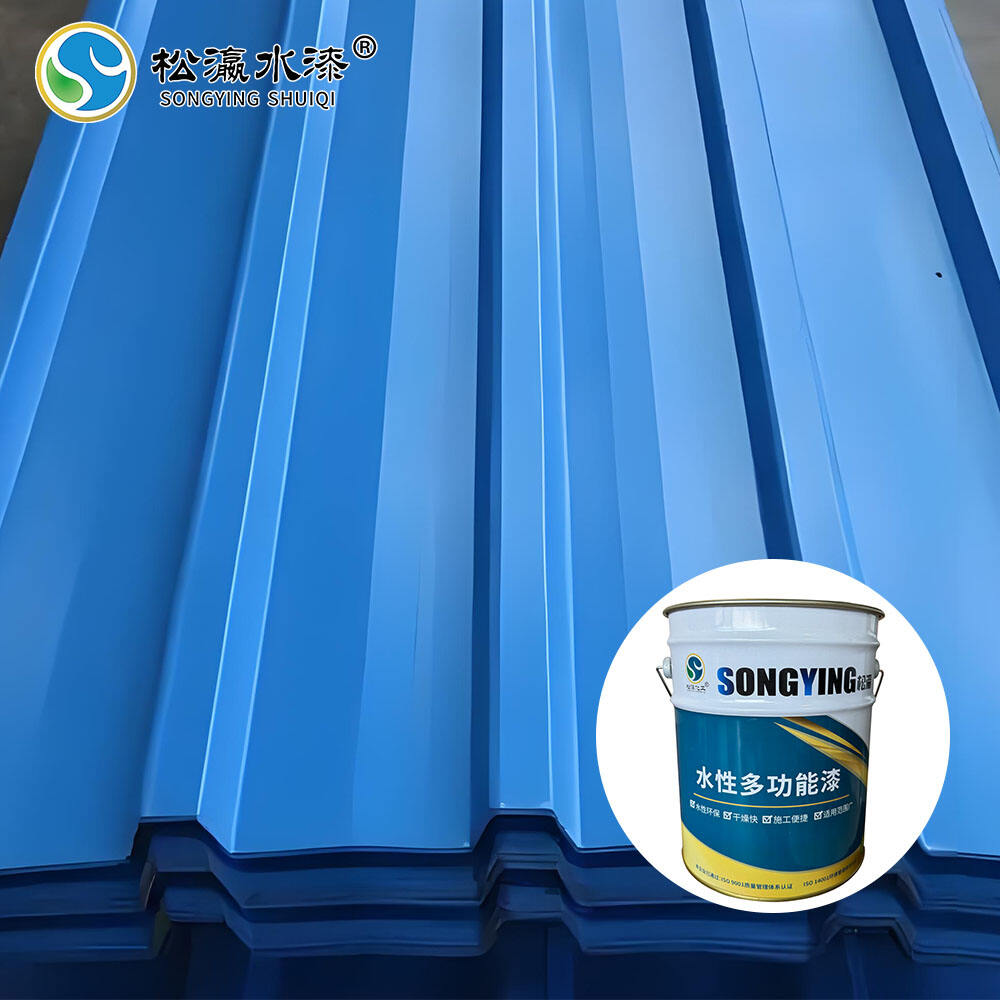

Cat Pelindung Berasaskan Air Banyak Fungsi

Cat SongYing Multi-Fungsi Berasaskan Air memberi penyelesaian mesra alam tanpa mengorbankan prestasi, menjadikannya pilihan ideal untuk pelbagai aplikasi maritim. Formulasi berasaskan air ini biasanya mengandungi sebatian organik mudah meruap (VOC) yang lebih rendah, selari dengan piawaian dan peraturan persekitaran moden. Kebolehtelapanan cat ini membolehkannya digunakan pada pelbagai permukaan, memudahkan pengurusan inventori serta kecekapan operasi bagi pengusaha kapal.

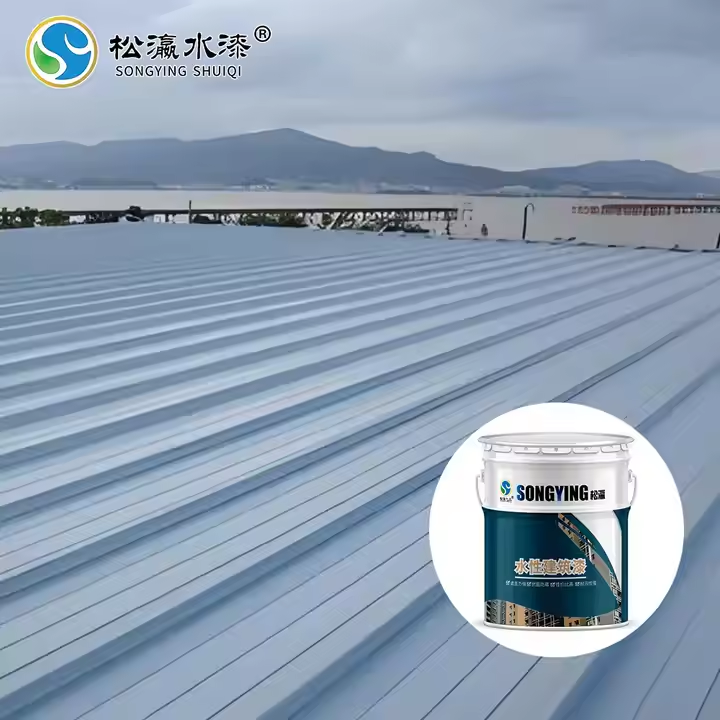

Penutup Atap & Dinding Akrilik Tahan Cuaca

Salutan Bumbung & Dinding Akrilik Tahan Cuaca SongYing direka bentuk untuk bertahan daripada keadaan cuaca yang melampau sambil mengekalkan kualitinya dari masa ke masa. Salutan akrilik ini turut diketahui tahan terhadap kulat dan karat, memberi kelebihan khususnya dalam persekitaran maritim di mana masalah-masalah ini sering berlaku. Dengan memilih salutan tahan cuaca, pemilik kapal dapat memanjangkan jadual penyelenggaraan, seterusnya menjana penjimatan kos yang ketara sepanjang hayat kapal.

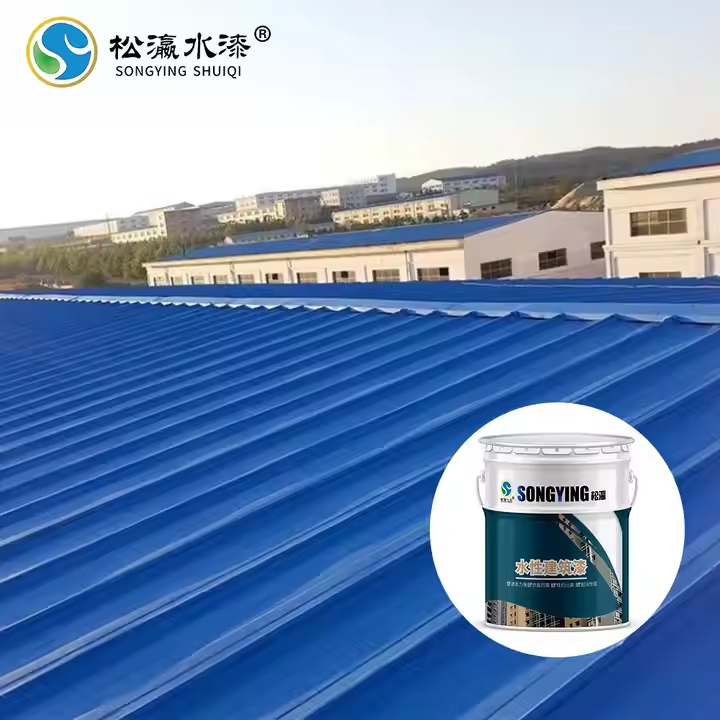

Sistem Restorasi Atap Logam Poliuretan

Sistem Pembaharuan Atap Logam Poliurethane dari SongYing menawarkan penyelesaian yang tangguh dan bertahan lama untuk atap logam maritim, melindunginya dari korosi dan aus umum. Pelapis poliurethane dikenal dengan kekuatannya, mampu menahan lingkungan kimia yang keras yang sering ditemukan di laut. Melaksanakan sistem pembaharuan ini dapat mengurangi keperluan penggantian penuh atap, memberikan alternatif penghematan biaya kepada pengendali kapal.

Impak Alam Sekitar Pelapisan Maritim Modern

Alternatif Berkelanjutan kepada Produk Antifouling Tradisional

Industri kelautan sedang beralih kepada alternatif yang lestari berbanding produk antifouling tradisional, dengan matlamat untuk meminimumkan kerosakan ekologi sambil mengekalkan prestasi. Penyelidikan dan pembangunan terkini telah fokus kepada bahan antifouling yang tidak toksik yang secara signifikan mengurangkan impak ekologi. Peralihan ini tidak hanya mematuhi peraturan alam sekitar tetapi juga memastikan keupayaan organisme laut untuk berkembang, mencerminkan keseimbangan antara fungsi dan tanggungjawab alam sekitar. Syarikat kelautan yang berdedikasi kepada amalan ramah alam sedang memperhatikan peningkatan dalam reputasi mereka dan menarik pelanggan yang menyedari isu alam sekitar. Dengan melabur dalam pelapisan yang lestari ini, syarikat boleh memainkan peranan penting dalam pelestarian laut sambil memprojeksikan imej yang progresif.

Kepatuhan Peraturan dalam Operasi Pengangkutan Global

Dalam lanskap pengangkutan global hari ini, menjaga ketaatan peraturan adalah perkara penting bagi operasi, terutamanya berkaitan dengan pelapisan kelautan. Syarikat harus melalui matriks yang kompleks dari peraturan tempatan dan antarabangsa, yang jika diabaikan, boleh menyebabkan denda besar dan kerosakan reputasi. Selain itu, ketidaktaatan boleh menghadkan secara ketat keupayaan operasi, mempengaruhi keupayaan untuk bergerak dengan lancar melalui pelbagai pasaran global. Menyemak kemas perkembangan kerangka peraturan tidak hanya melindungi daripada denda yang mungkin berlaku tetapi juga menyokong operasi yang lebih lancar di pelbagai rantau global. Pendekatan proaktif ini memastikan syarikat dapat menyesuaikan diri dengan perubahan peraturan, mencetuskan pertumbuhan dan kecekapan operasi.

EN

EN